4 Simple Techniques For Sheroz Earthworks

More About Sheroz Earthworks

Table of ContentsFacts About Sheroz Earthworks RevealedThe Single Strategy To Use For Sheroz EarthworksSheroz Earthworks Fundamentals ExplainedThe Facts About Sheroz Earthworks Revealed8 Simple Techniques For Sheroz Earthworks

For any type of earthwork specialist, it is vital to perform job with quality, precision, and on time. Utilizing machine control in job machines makes it possible for optimizing the various stages in the earthwork procedure, from preparing to the maintenance phase - trimble repair parts. The machine control system helps the machine operator in achieving the target aircraft rapidly and quickly

The machine control system overviews the driver with centimeter precision. Remote assistance saves time and money, as it minimizes downtime in jobsites.

The Of Sheroz Earthworks

Added training and instructions are always offered over remote assistance when required. The earthmoving sector has used our field-proven options because the early 1990s. Our system's elements are meticulously created to endure the rough conditions of building sites. Contrast of the very same task performed utilizing machine control versus the typical technique discloses that, usually, the standard method needs 50% even more time to accomplish the exact same job as the technology-assisted method. https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck.

Seems good? Go into the Xsite machine control system; it's here to supply you with a substantial advantage when collaborating with earthmoving equipment. Discover exactly how Xsite Machine Control can improve your productivity and guarantee work safety! We understand that finding out a brand-new modern technology could seem like a drag, but don't fret! Our friendly and professional local assistance services have actually got you covered, making certain that you can keep working smarter without interruptions while on the job! Via remote assistance, your neighborhood Xsite dealership can supply guidance or troubleshooting without needing to visit the site! What kind of excavators does equipment control fit? Xsite Device Control systems can be set up to any excavator from mini excavators to big mining excavators.

How does maker control work? In 2D systems, the equipment is equipped with adjusted inclination sensing units. These sensing units are mounted on the pre-determined components of the machine in excavators the sensing unit are usually mounted to the framework, boom (or booms), miner arm and to the fast coupler - trimble gps. By utilizing the data received from these sensing units the system can calculate the precise placement of the excavators bucket suggestion in significance to a referral factor.

The system is very simple to discover the fundamentals can be instructed in under one hour of training. Exactly how does the remote assistance job? A cordless web connection makes it feasible to establish a remote link in between the machine control system and the solution.

3 Easy Facts About Sheroz Earthworks Shown

What kind of information styles Xsite systems support? Xsite Device Control systems sustain open common file styles, making it possible for seamless info flow from one system to an additional. Supported documents formats: 2D-Maps: DXF Factor documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What parts are mounted on my maker? Depending upon your choice of system (with or without positioning, i.e - trimble gps., 2D or 3D), your equipment is outfitted with disposition sensing units, a controller unit, and a display/operating panel.

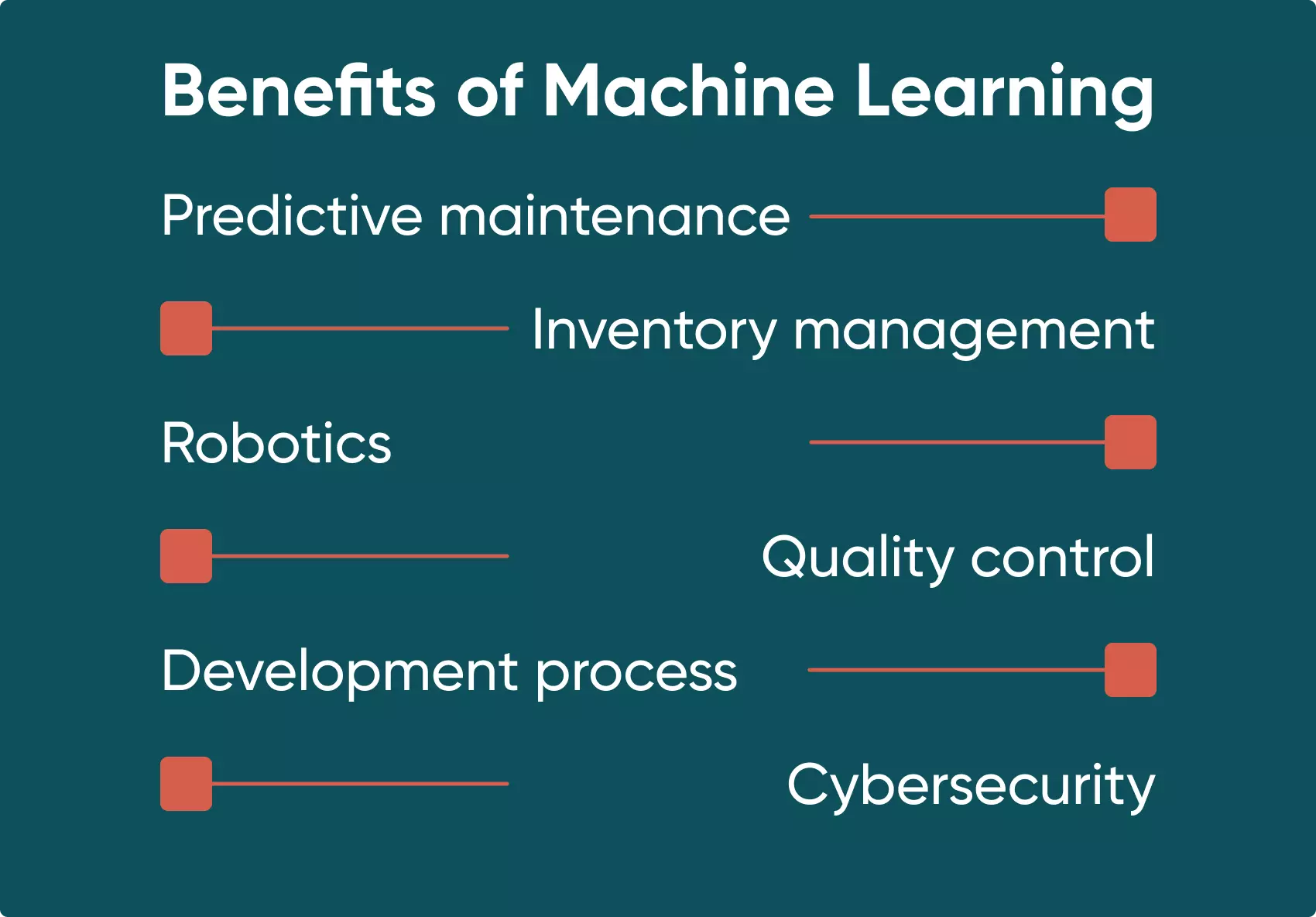

Several software and hardware services exist to aid identify an equipment's current placement on the planet and contrast it with a desired design surfaceand construction drivers can do more to utilize the advantages. Maker control is making use of different placing sensors and a display screen to supply the operator with a recommendation in between the placement of the container or blade and the target grade.

Depending on the setup, device control systems can supply the driver with a straightforward aesthetic guide to bucket or blade setting, or can automatically move the blade to grade by speaking with the equipment's hydraulics - https://www.giantbomb.com/profile/sherozau/. There are equipment control systems offered for nearly any type of equipment: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, milling machines, and pavers

A Biased View of Sheroz Earthworks

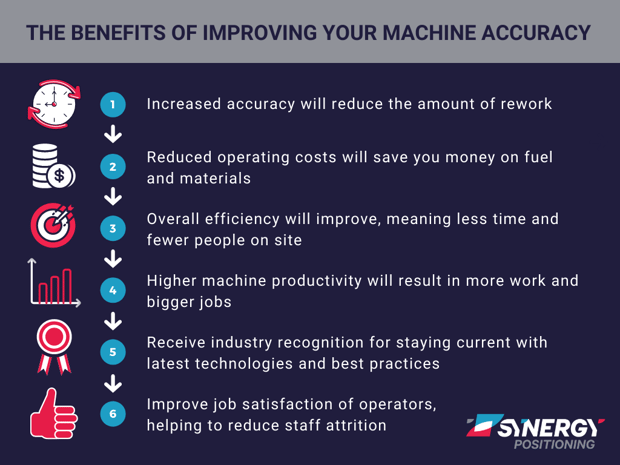

Some benefits include minimized rework, boosted job performance, and lower evaluating costs. Maker control can likewise aid enhance productivity and minimize total costs. This technology is transforming the means the building and construction market functions. Building tools without equipment control will certainly come to be a thing of the past and the advantages obtained from it will be numerous.

Trimble maker control systems supply a you can check here myriad of benefits to anyone who makes use of earthwork equipment and, at EarthCalc, we can give you with 3D declare your equipment control-enable tools. Uncertain if device control is worth the expense? Consider the adhering to reasons that you need to consider this option.

Using general practitioner straightened with your 3D design files, these systems practically ensure that you will certainly remove or place the appropriate amount of material at the building site. On a lot of construction sites, rework is an usual and irritating reality, yet with Trimble equipment control, you can get rid of the need for rework.

Excitement About Sheroz Earthworks

Commonly, with Trimble machine control, you can remove excess equipment at a particular task site. A job that might have called for the usage of three or 4 items of excavating tools currently might require only two pieces of equipment to accomplish the same task in less time. This permits you to relocate your tools to another task site and deal with multiple work at once.